Services

We know you have a lot of options when choosing a machine shop, and we strive to differentiate ourselves by operating far beyond expectations. Our commitment to reliability, honesty and fairness equals our commitment to doing a job well. It’s the reason we’ve had customer relationships that have lasted for decades.

CNC Machining

Computer Numerical Control (CNC) machining is a manufacturing option that uses a combination of computer assisted designs and sophisticated cutting tools to remove materials from a solid block, leaving a shaped component. CNC enables high-tech machines to make components with complex geometries that would be too time-consuming using a manual process. Bronco Machining & Manufacturing Inc. offers a wide range of CNC machining services for small, medium and large manufacturing operations in industries such as aerospace, government and medical.

Parts created with CNC machining are precise, reliable and durable. Bronco Machining & Manufacturing Inc. is equipped with 3-axis, 4-axis, and 5-axis machining automation to manufacture the most complicated components, including complex prototypes. Bronco Machining & Manufacturing Inc. uses the latest computer software to enable complete integration with your company’s CAD/CAM design files. This allows Bronco Machining & Manufacturing Inc. to download custom drawing files directly from your engineers, thus streamlining the whole process.

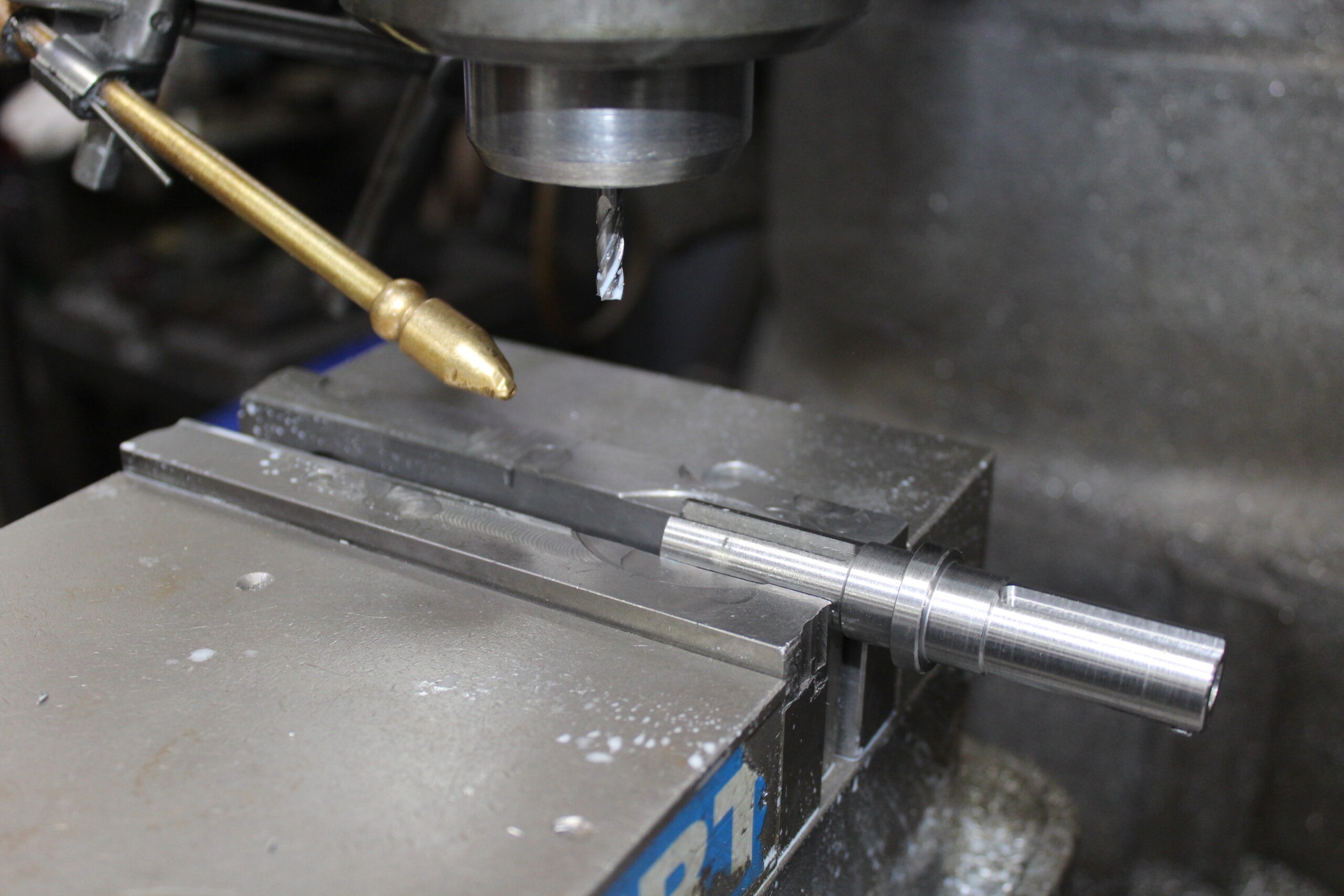

Milling

CNC Milling is one of our specialities. Our CNC milling service is the ideal process for complex shapes with high dimensional tolerances. We can mill with up to 5 axes on our modern machining centres.

We have the ability to work with many different materials – including but not limited to aluminum, stainless steel, alloy steel, copper, brass, bronze, iron and more.

CNC Turning Manufacturing

Turning is a manufacturing process that is used to produce a wide variety of parts. In addition to cylindrical parts, can be used to produce parts with complex shapes, such as gears and threads.

The process is versatile and can be used to produce parts in a variety of shapes and sizes. We use the latest precision CNC machines to produce parts that meet the highest standards of quality and precision.

At Bronco Machining & Manufacturing Inc., we have a team of experienced engineers who can help you design and manufacture parts that meet your specific requirements.

MIG & TIG Welding for a Variety of Applications

MIG welding is a widely used arc welding process suitable for minor repairs and joining. It uses wire welding and is used for automotive welding and general repairs. The greatest advantage to MIG welding is the speed. This method allows us at Bronco Machining & Manufacturing Inc. to finish your project quickly and efficiently so we can return your equipment to you in a timely manner.

Used to create joints, bends, and other aspects of custom metal fabrication, MIG welding is ideal for office furniture, car frame repair, metal construction work, and other minor projects. This type of welding is highly versatile because of its many applications on different metals, including stainless steel, low alloy steel, aluminum alloys, copper alloys, and nickel alloys.

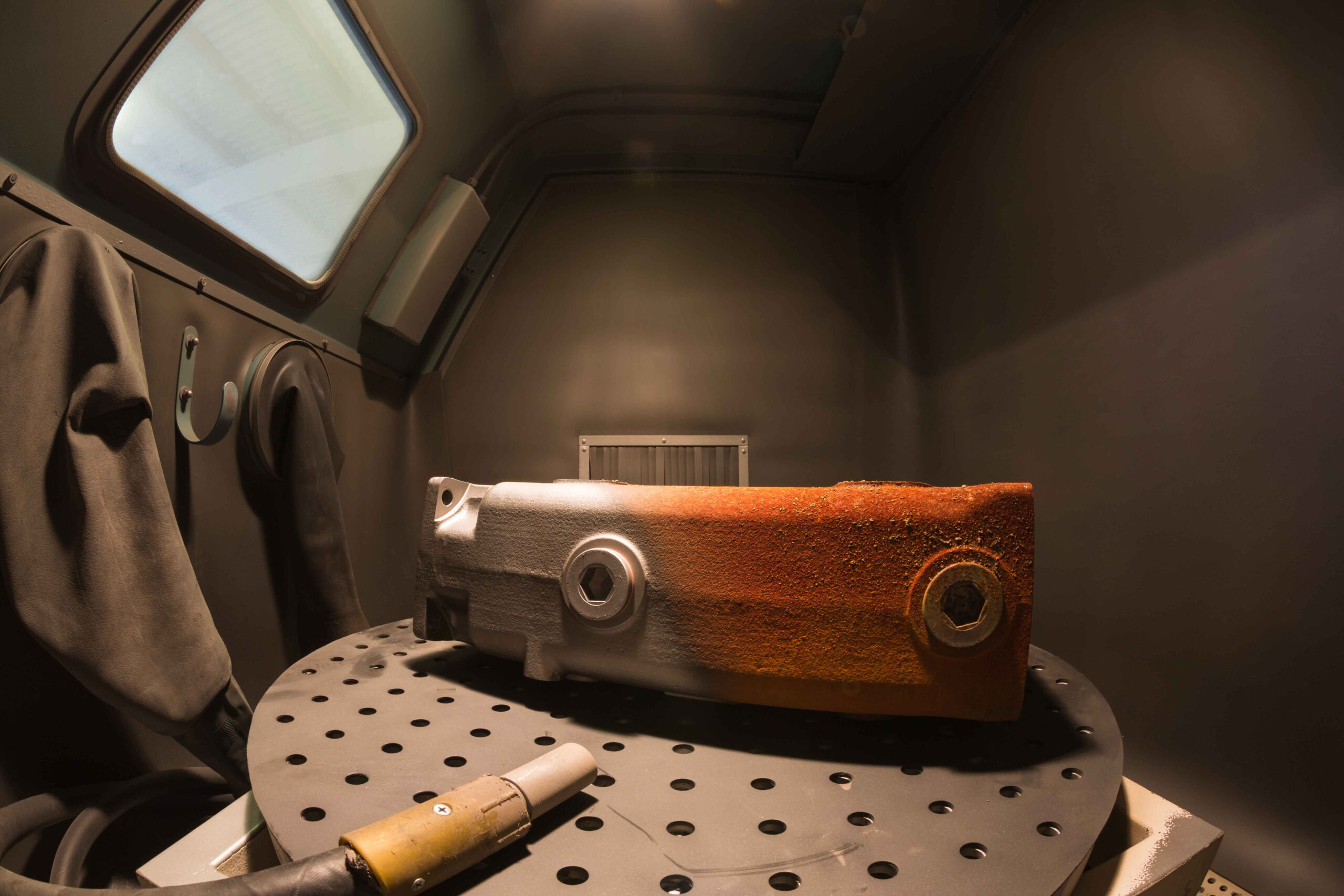

Sandblasting

Sandblasting is one of the most effective ways to quickly remove paint, rust, and other foreign materials. It is a flexible preparation method that creates a surface with fewer physical imperfections. It also provides a uniform or etched surface that increases the mechanical and chemical bond to future coatings.

There are many different media available for the abrasive blasting process. They range from highly abrasive to more mild variants. We will recommend the best media for your sandblasting or coating project, whether you’re looking to make a rough surface smooth or vice versa.

Metal Polishing

Bronco Machining & Manufacturing Inc. has performed high quality metal polishing services with a special focus on highly complex, custom projects. Our processes, which include automated, mechanical and hand metal polishing leverage the expertise of our skilled operators as well as our state-of-the-art equipment.

At Bronco Machining & Manufacturing Inc., we can take on large parts up to 20 ft. long and virtually any width, height and weight. We’re adept at polishing myriad shapes, from fabrications, castings, forgings, stampings, spinnings and machined parts in substrates such as brass steel, aluminum, stainless steel, titanium and beryllium.

Breakdown and Repairs

When your company is facing a tight deadline and you rely on your equipment to produce, the prospect of a breakdown brings tremendous stress. At Bronco Machining & Manufacturing Inc., we know that you cannot wait weeks or months for original equipment manufacturer parts to arrive. Our precision machining experts work with the customer to develop a specific plan to ensure that the customer will get back up and running as soon as possible. Plans might include new parts per sample, simple repair, or temporary repair during manufacturing.

Even the sturdiest parts wear down after a while: bores grind down, shafts lose their integrity, contact surfaces wear away. At Bronco Machining & Manufacturing Inc., we can return your parts to their original specifications, working closely with you to precisely determine the original dimensions. Our engineers are experienced in weld build up, metalizing, chroming and sleeving, quickly returning your machines to working order.

About Us

We specialize in precision machining from single prototypes to the production of thousands of pieces. We are capable of handling all of your CNC machining and turning needs in varied materials and processes.

Quick Links

Powered By:

Aguilera Web Design© Copyright 2022 Bronco Industries